PROJECTS

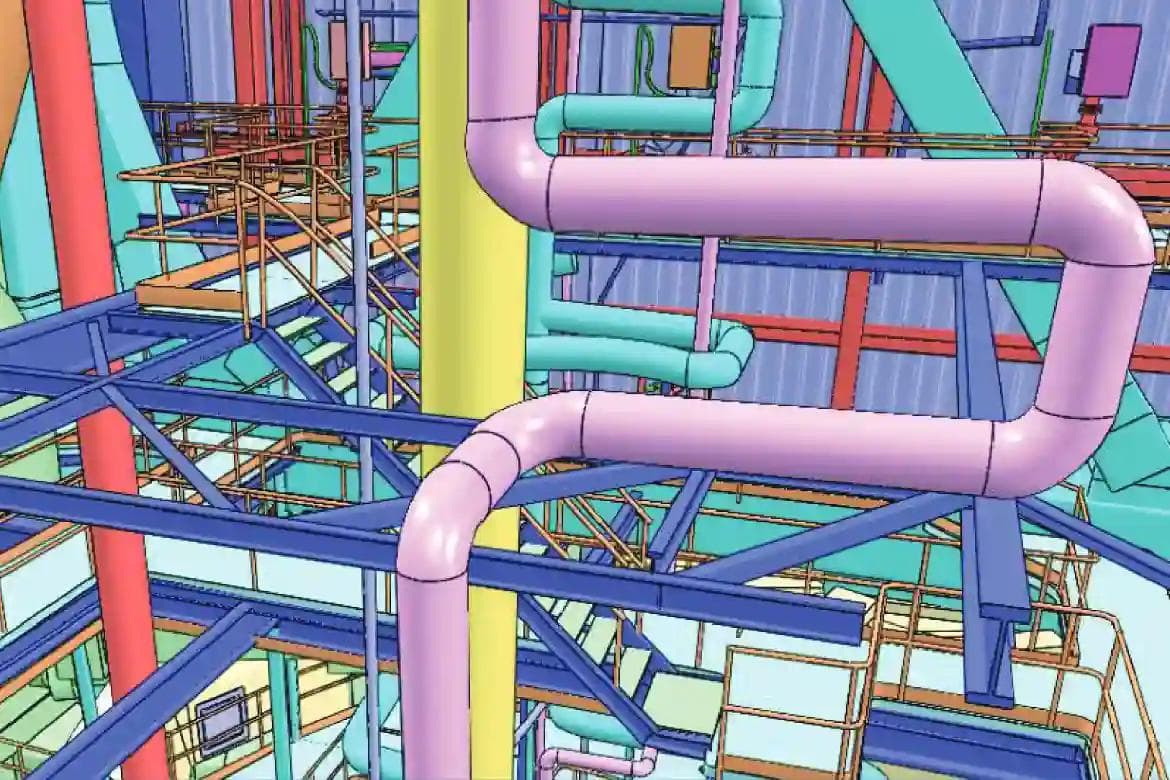

3D Laser Scanning and Data Processing & AS-Build 3D PDMS Model & Poly Mesh 3D

Service: 3D Laser Scanning and Data Processing, AS Built 3D PDMS Model, Poly Mesh 3D Model

Location: Kosovo B

Time: November 2023 - January 2024

Project Overview

We conducted 3D laser scanning over three days, capturing data at 377 scanning spots in black and white. The scanning data was processed within seven working days using SCENE software and exported as an .e57 file. From the point cloud data, we extracted a Poly-Mesh geometry to ensure a detailed and clean representation of the scanned elements. This process included the separation of boilers, ducts, metal construction, metal platforms with equipment, and pipe routes from all levels. This data can be used for detailed inspections and condition assessments of the equipment and elements.

3D Laser Scanning and Data Processing & AS-Build 3D PDMS Model & Poly Mesh 3D

Service: 3D Laser Scanning and Data Processing, AS Built 3D PDMS Model, Poly Mesh 3D Model

Location: Kosovo B1

Time: July 2023 - October 2023

Project Overview

We conducted 3D laser scanning over three days, capturing data at 352 scanning spots in black and white. The scanning data was processed within seven working days using SCENE software and exported as an .e57 file. From the point cloud data, we extracted a Poly-Mesh geometry to ensure a detailed and clean representation of the scanned elements. This process included the separation of boilers, ducts, metal construction, metal platforms with equipment, and pipe routes from all levels. This data can be used for detailed inspections and condition assessments of the equipment and elements.

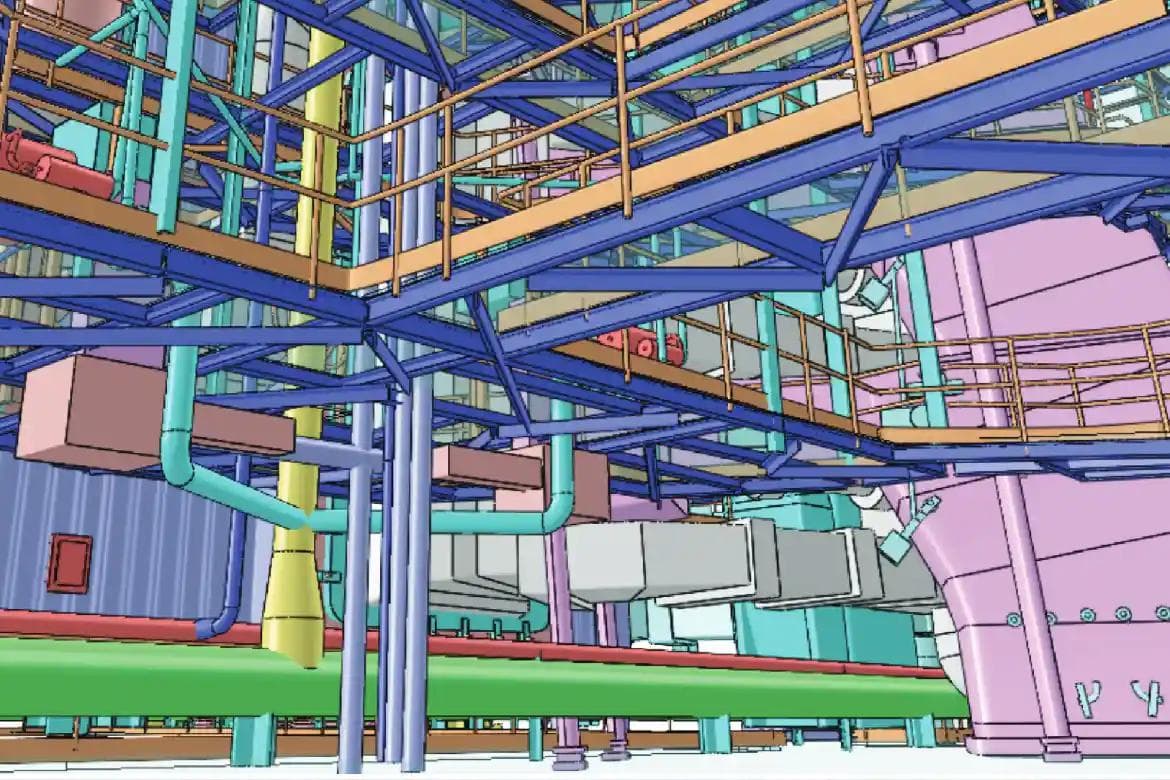

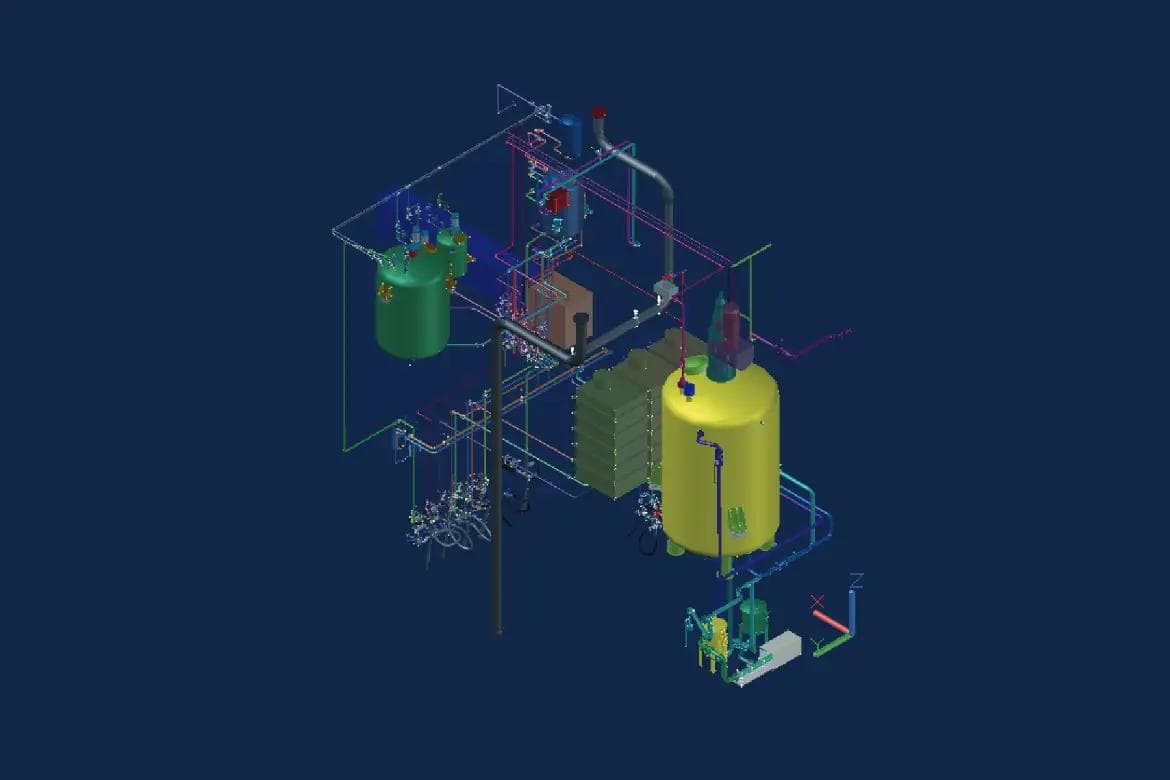

AS Build CAD Model from Point Cloud

Service: As-Build 3D Modeling, Clash Report, 3D Data Optimization

Location: USA

Time: December 2022 - February 2023

Project Overview

We created an as-built 3D model of the current situation from point cloud data, providing comprehensive data management and grouping in families for each system. The project included water systems, powder dosing systems, process equipment, pressured air, instruments and electric, civil, and architectural elements. Our service also covered 3D data optimization and synchronization for the client's preferred software solution, making the data easy to open and work with. Additionally, we optimized the 3D model for future equipment installation and conducted a clash report.

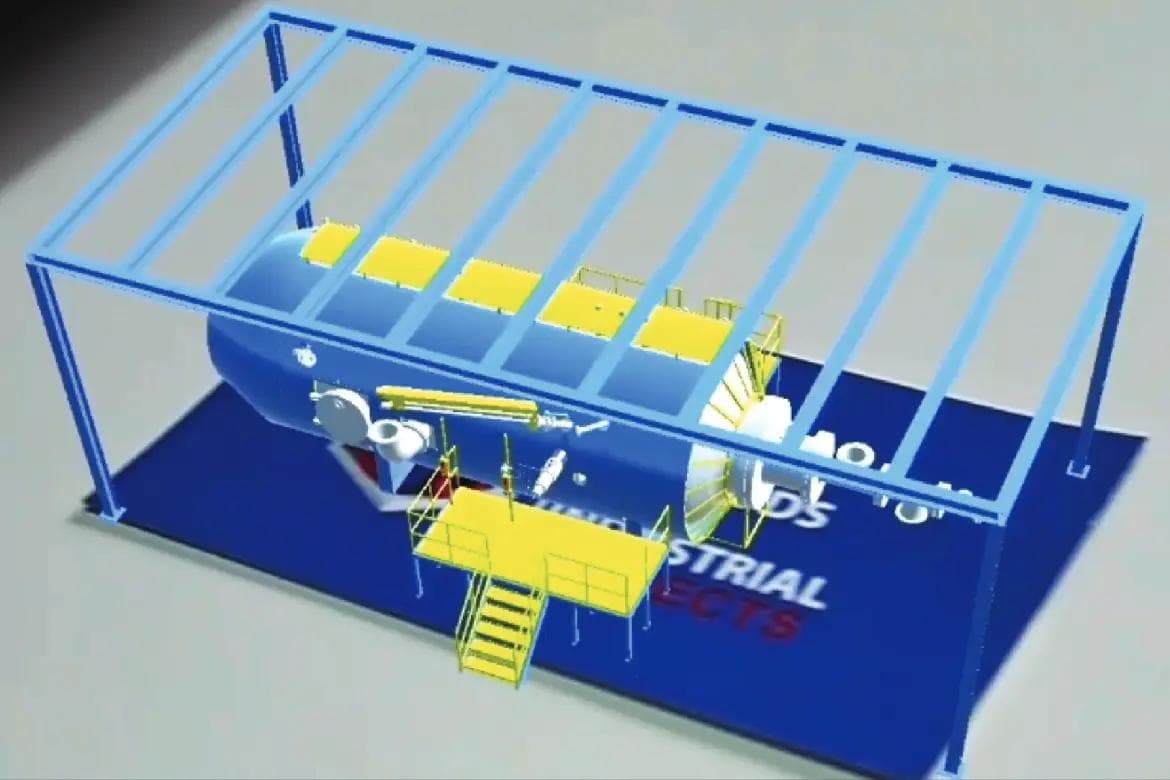

Poly 3D Modeling & AR Unity Mobile App Development WebGL

Service: Poly 3D Modeling | AR Unity Mobile App Development | WebGL

Location: USA

Time: September 2022 - December 2022

Project Overview

To facilitate the presentation of a mechanical assembly from a tank on the web and in augmented reality (AR), we optimized the provided 3D data for VR, AR, and WebGL. This project involved remodeling parts of the assembly into polygon geometry and developing a mobile application in Unity 3D for AR presentation. We successfully reduced the data size by 100 times, ensuring efficient performance and accessibility.

BIM Model, 3D Modeling, Intelligent Links and Tagging

Service: BIM Model, 3D Modeling, Creation of Intelligent Links and Tagging

Location: N/A

Time: February 2022 - April 2022

Project Overview

We developed an LOD 500 BIM MEP 3D model from point cloud data for a client under NDA. The project encompassed architectural, structural, piping, electrical, instrumentation, mechanical, and safety equipment elements. The integration included the use of intelligent links and tagging, ensuring comprehensive and efficient data management.

As-Built CAD Model from Point Cloud

Service: As-Built 3D Modeling, 3D Data Optimization

Location: Confidential

Duration: December 2021 - January 2022

Project Overview

For this project, we developed a detailed As-Built 3D model using point cloud data, which included comprehensive data management and tagging for each part and system. The focus was on optimizing the 3D data for seamless integration into the client's preferred software solution, making it easy to open and manipulate. Additionally, the model was tailored for future equipment installation, ensuring maximum usability.

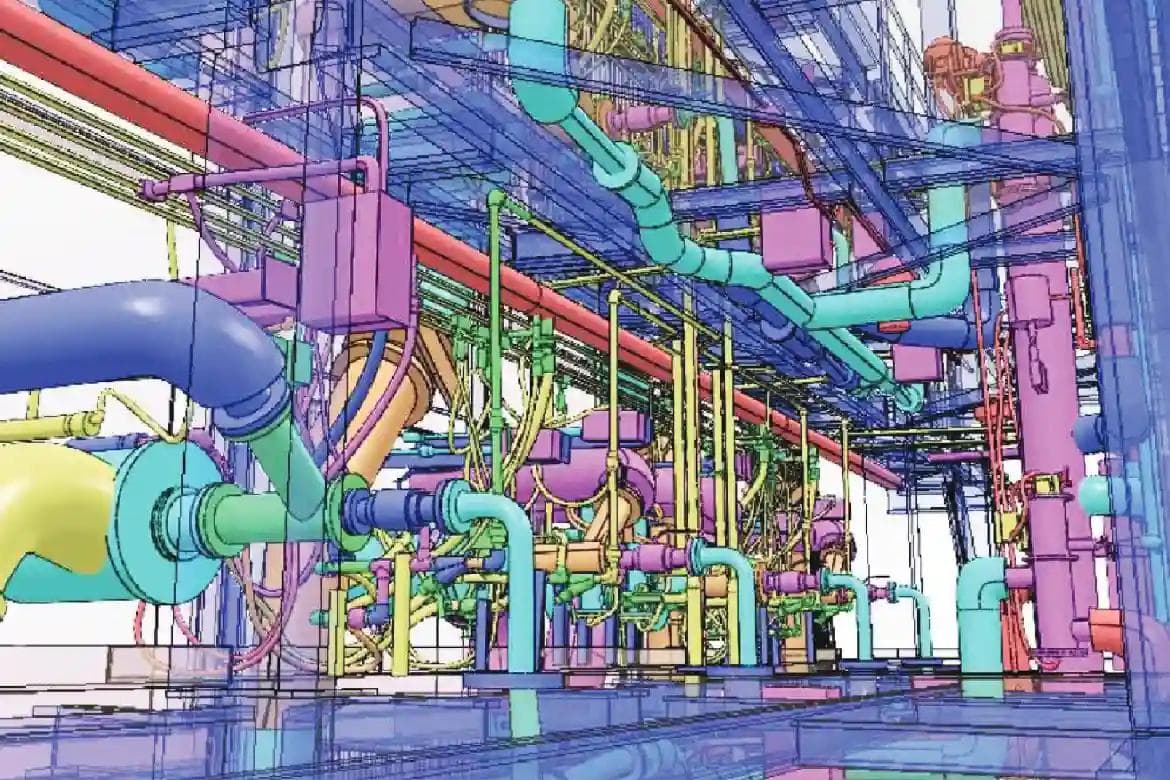

BIM Revit MEP Model of Hot Water Generator

Service: BIM Model, 3D CAD Modeling, Creation of Families

Location: N/A

Time: November 2021 – December 2021

Project Overview

We developed an LOD 500 BIM MEP 3D model from detailed 2D drawings, focusing on the hot water generation building. This comprehensive project included 3D modeling of pipelines for hot and cold water, as well as detailed 3D CAD modeling of mechanical equipment. The project utilized Autodesk Revit for the primary BIM modeling, with additional equipment modeling done in AutoCAD 3D and SolidWorks.

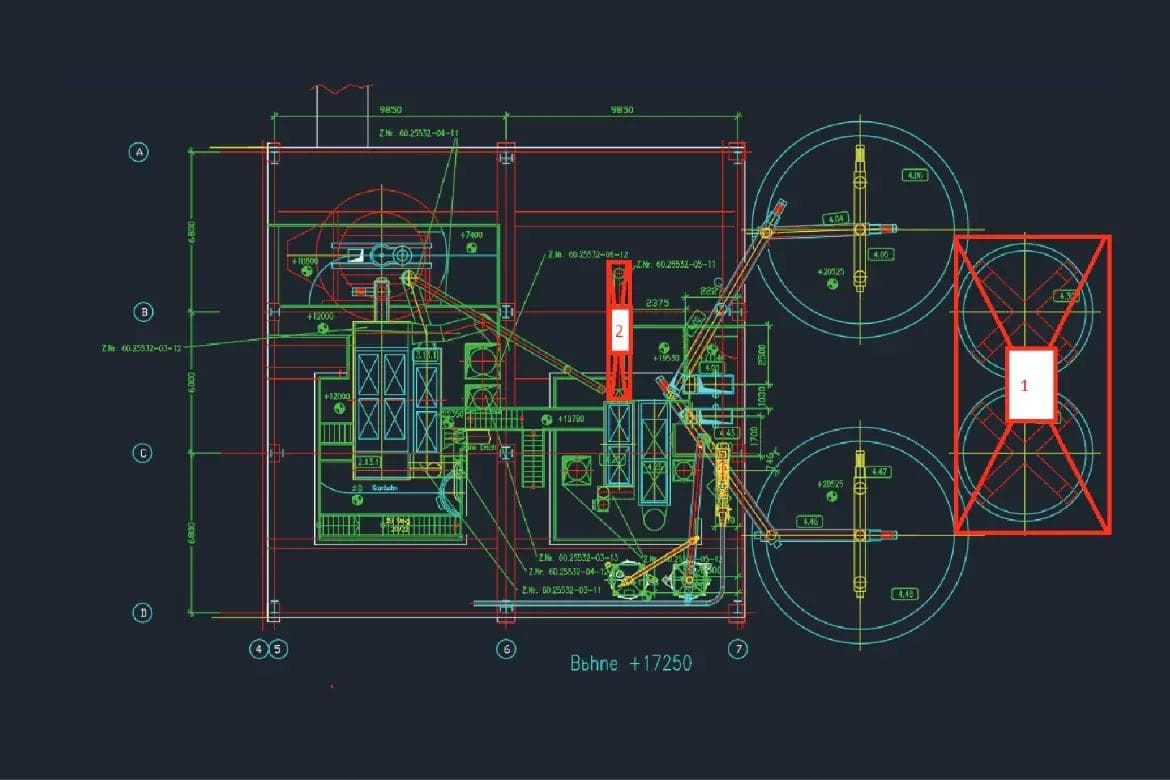

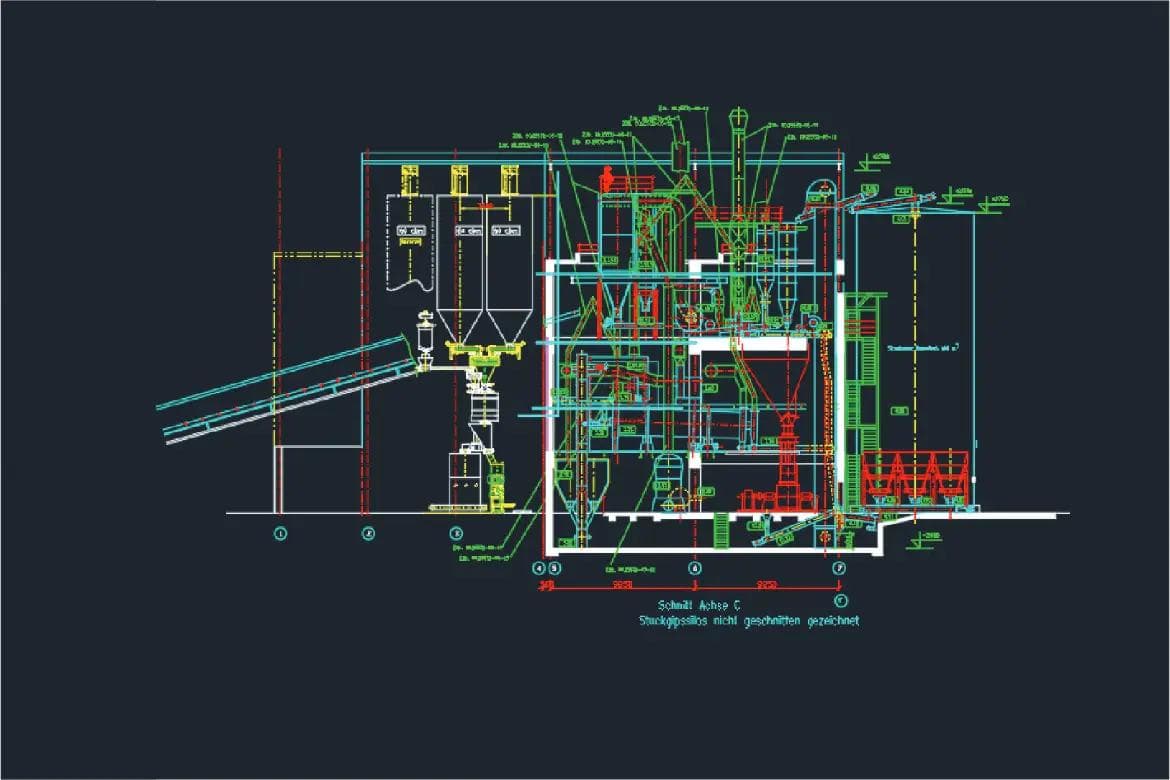

AS BUILD Drawings and Adjustments on Future Line

Service: AS-BUILD Drawings, Preliminary CAD Drafting for Future Rob Pack Automated-Packaging Line

Location: Debar, Macedonia

Time: October 2021 - November 2021

Project Overview

We conducted an on-plant survey and created as-built drawings to document the current state of operating equipment at Knauf Radica AD. This project involved preliminary CAD drafting to design and integrate a future rob pack automated-packaging line, ensuring seamless installation and operation.

3D Laser Scanning KEK Kosovo Power Plant

Service: 3D Laser Scanning on Boiler A and B, Laser Scanning Data Processing

Location: KEK Kosovo

Time: April 2021 - March 2021

Project Overview

We conducted 3D laser scanning on Boilers A and B at the KEK Kosovo Power Plant during a period of regular shutdown and overhaul. The purpose was to perform deformation analysis to aid in a feasibility study, providing documented data and conclusions for the plant's operational and structural assessment.

Digital Twin for Deformation Inspection

Service: CAD Model from Point Cloud Data, Inspection for Wall Deformation

Location: KEK Kosovo

Time: March 2021 - May 2021

Project Overview

We processed parametric data obtained from point cloud scans to create an accurate and optimized 3D CAD model for deformation inspection purposes. The project focused on analyzing wall deformations of a 65-meter high furnace using the SOLIDWORKS software solution.

Data Optimization and Virtual Reality

Service: Simulation of the Preliminary Design in Virtual Reality

Location: Skopje

Time: May 2020 - September 2020

Project Overview

In the preliminary design phase, we leveraged Virtual Reality (VR) technology to provide a detailed and realistic analysis of architectural, thermal, hydraulic, and electrical installations. This approach not only enhanced the sense of space and size but also facilitated innovative ideas and solutions.

Simulation of Method of Installation

Service: Simulation of the Method of Installation in 3D and Virtual Reality

Location: Skopje

Time: May 2020 - September 2020

Project Overview:

To create a detailed simulation in 3D and Virtual Reality for the installation activities required to prepare and build a new manufacturing capacity. This simulation aimed to ensure all activities were performed with high EHS (Environmental, Health, and Safety) standards.

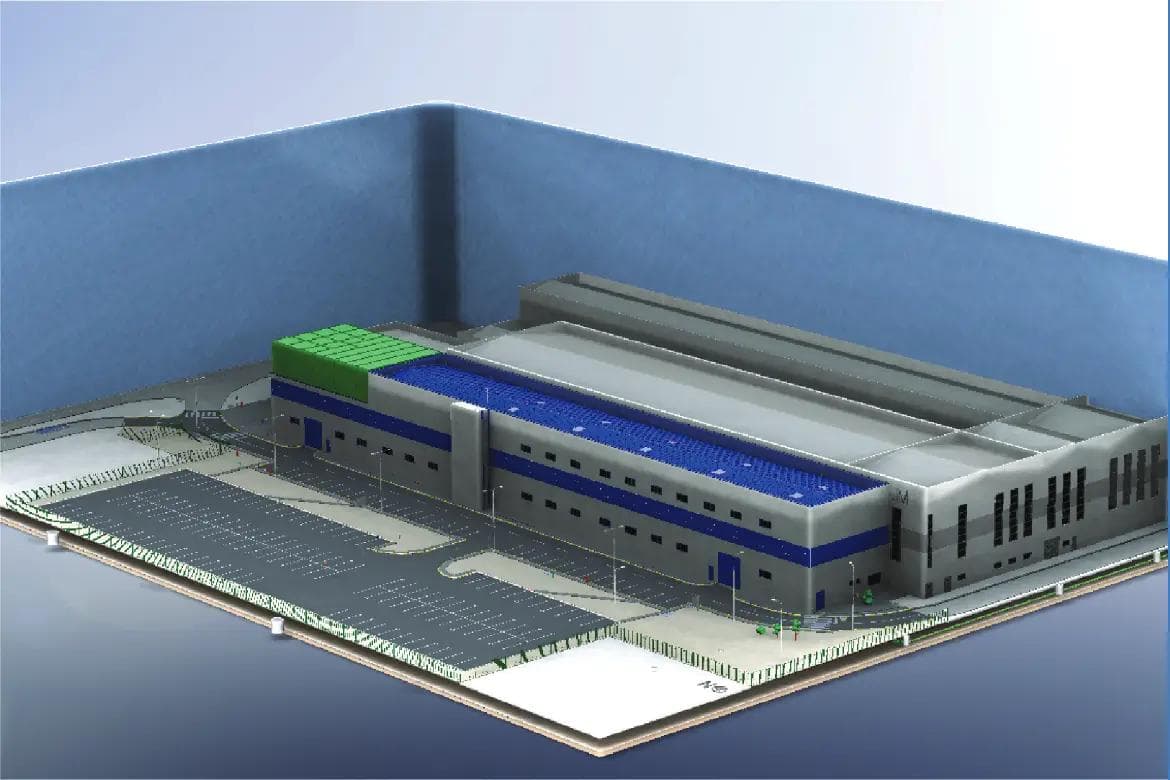

3D PDMS Support

Service: Intelligent 3D Model of As-Built Situation and Preliminary Design, Clash Report, 3D Data Optimization

Location: Skopje

Time: May 2020 - September 2020

Project Overview

We developed an as-built 3D model of the current situation, including the plant yard and car parking areas, where the preliminary design of the new manufacturing capacity was planned to be built. Starting from a detailed land survey, we created a CAD model which served as the foundation for the preliminary 3D CAD model.

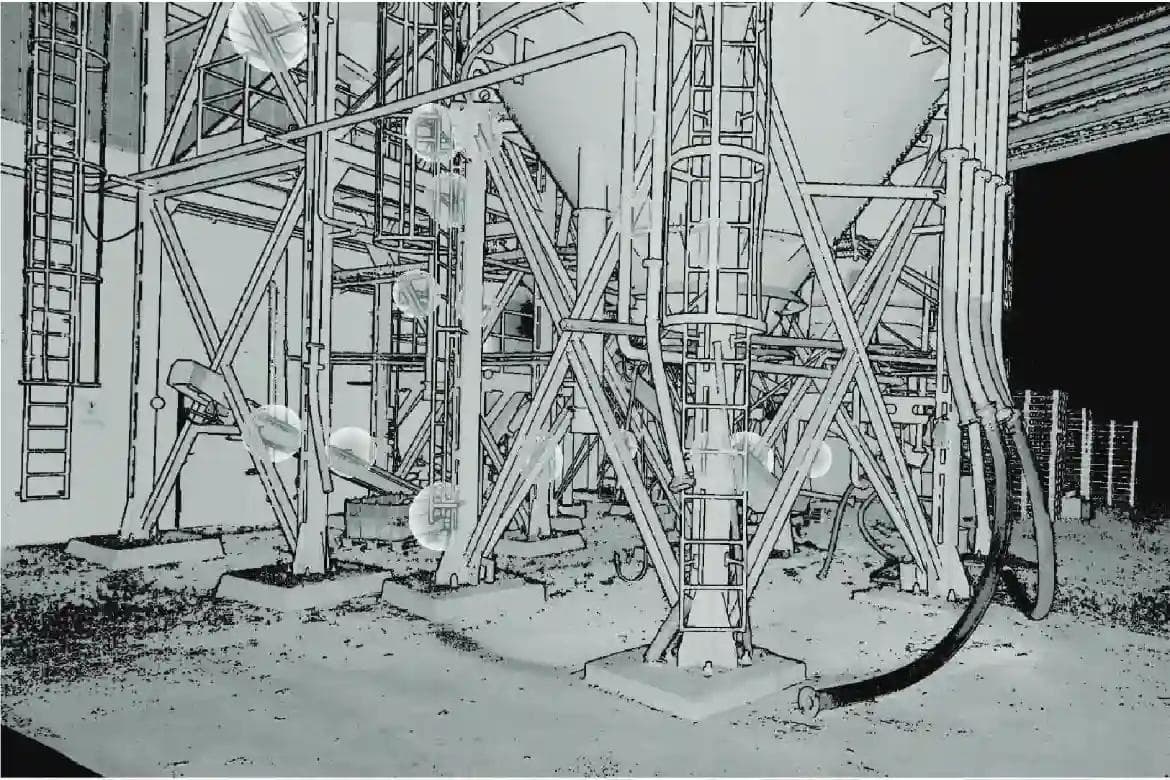

Update and Inspection on AS BUILT Drawings

Service: AS-BUILT Drawings, On-Plant Survey

Location: Debar, Macedonia

Time: January 2020 - February 2020

Project Overview

The project focused on conducting an on-plant survey and updating AS-BUILT drawings to reflect the current situation of operating equipment in the milling process. This was essential for planning activities aimed at upgrading the industrial capacity of the facility.

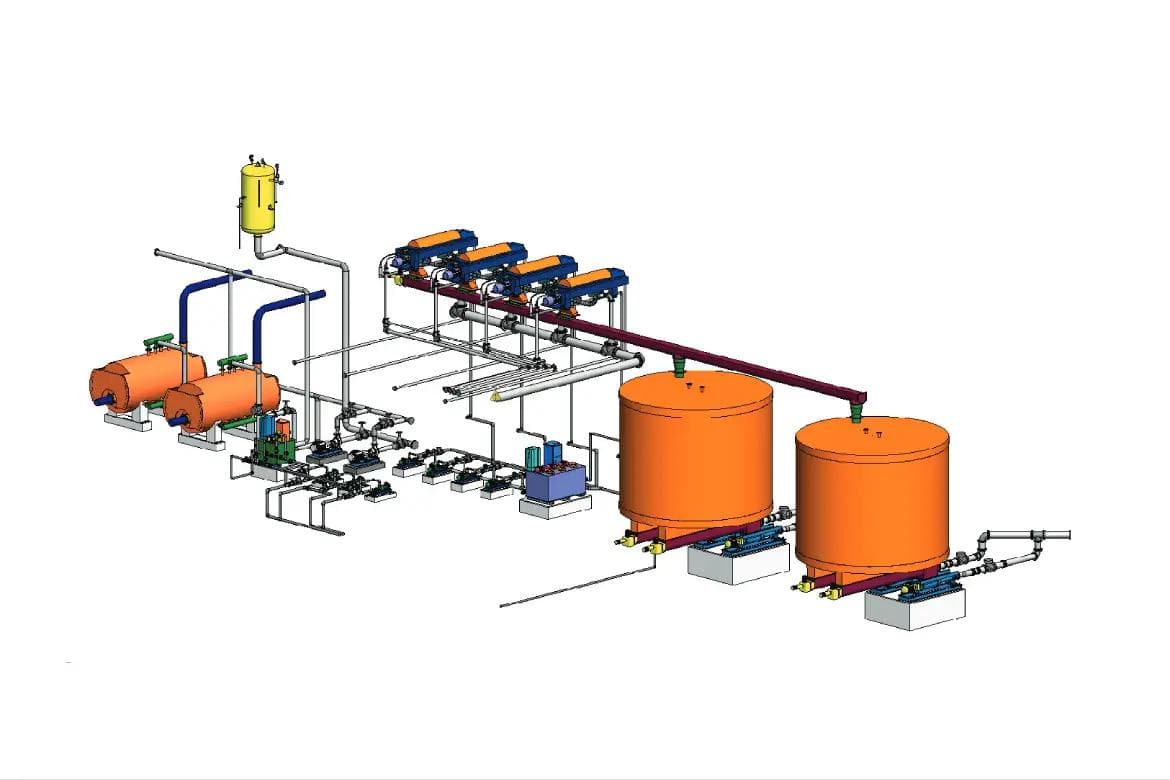

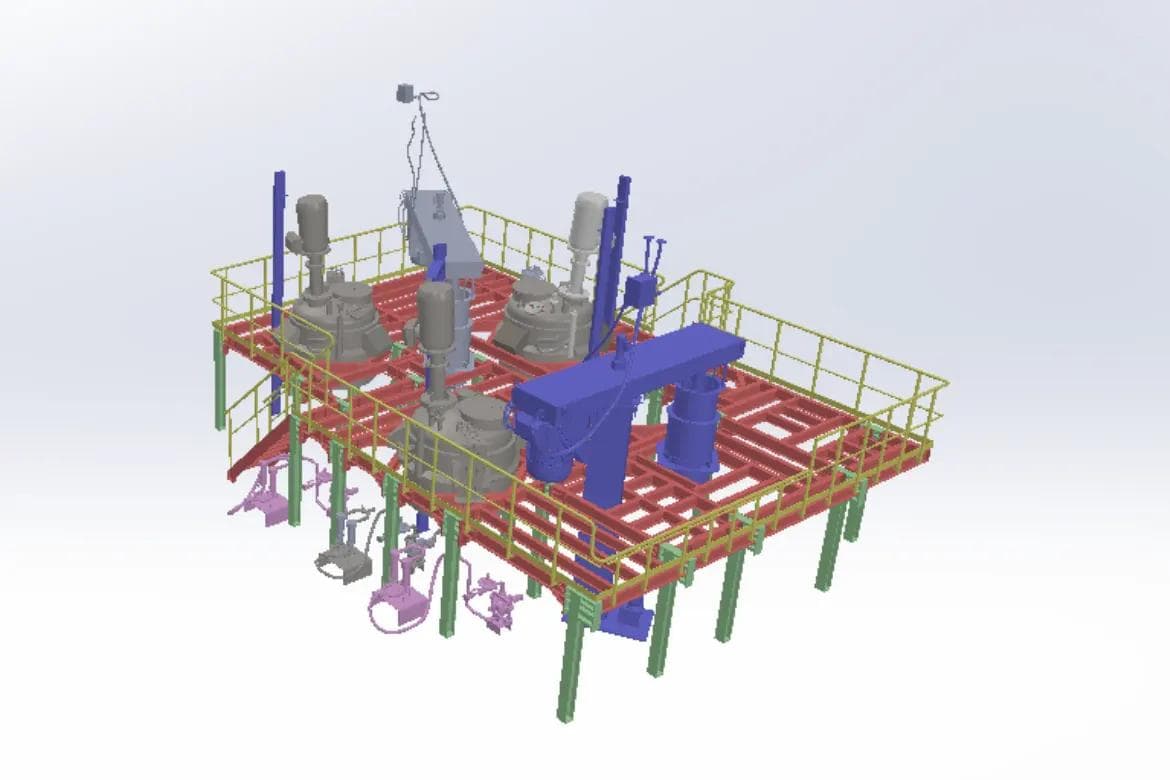

As-Built 3D Model | BOM Documentation | Data Optimization

Service: As-Built 3D Modeling, Clash Report, 3D Data Optimization

Location: Skopje

Time: December 2018 - March 2019

Project Description

The primary goal of this project was to create an accurate and comprehensive as-built 3D model of the current situation from point cloud data. This model would include various systems such as water, powder dosing, process equipment for milling and mixing, pressured air, instruments and electric, civil, and architecture. Additionally, the project aimed to optimize 3D data for improved usability and synchronization with the client's preferred software.

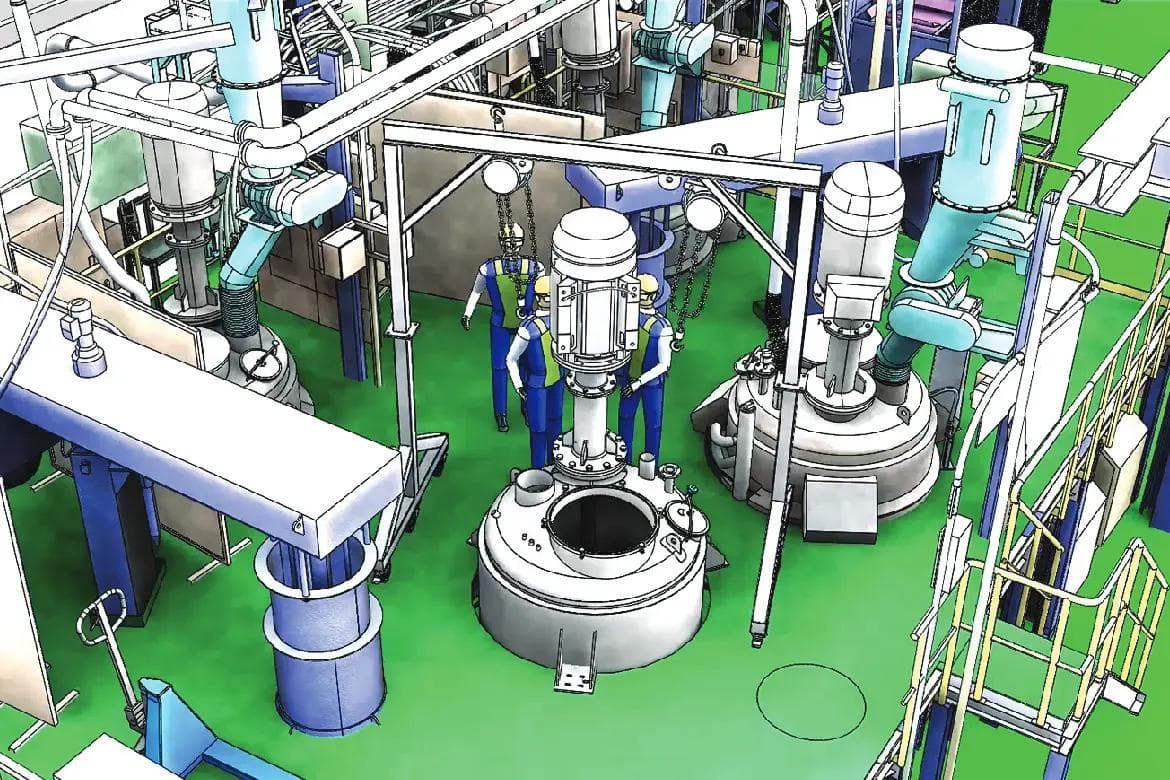

Simulation of Method of Installation in CAD Environment

Service: Simulation of Method of Installation in CAD Environment

Location: Skopje

Time: December 2018 - March 2019

Project Overview:

The project aimed to create a comprehensive simulation in a CAD environment for the installation activities related to new equipment. This simulation covered all preparation activities based on the as-built model, step-by-step actions, timelines for each system, and the utilization of necessary tools and machinery while adhering to high Environmental, Health, and Safety (EHS) standards. Clash reports and analysis were integral parts of this simulation, ensuring smooth coordination and execution of the installation process.