3D PDMS Support

Service: Intelligent 3D Model of As-Built Situation and Preliminary Design, Clash Report, 3D Data Optimization

Location: Skopje

Time: May 2020 - September 2020

Project Overview

Description:

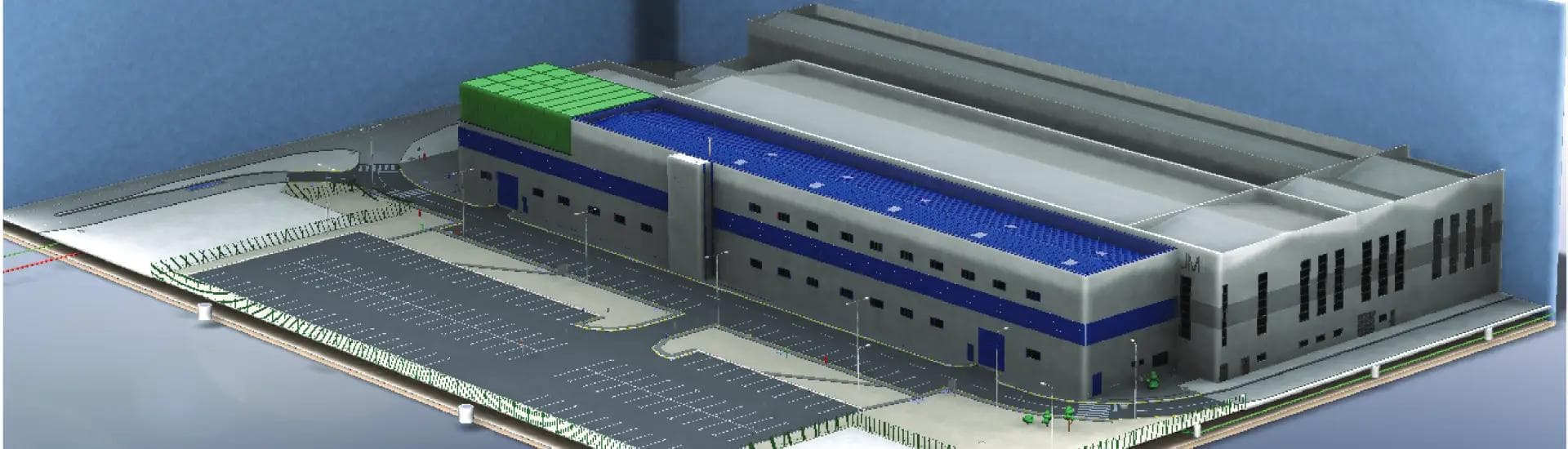

We developed an as-built 3D model of the current situation, including the plant yard and car parking areas, where the preliminary design of the new manufacturing capacity was planned to be built. Starting from a detailed land survey, we created a CAD model which served as the foundation for the preliminary 3D CAD model.

Scope of Work:

1.As-Built 3D Modeling:

Created an accurate 3D model of the existing plant yard and parking areas based on comprehensive land surveys.

Used this model as the starting point for the preliminary design of the new manufacturing facility.

2.3D PDMS Model Development:

Collaborated with company and individual designers responsible for architectural, electro-technical, hydro technical, thermal-technical, and sprinkler systems.

Converted 2D drawings and plans into an integrated 3D CAD model.

Conducted 3D data processing and optimization to incorporate various design elements into a single, cohesive CAD model.

3.Clash Analysis and Redesign:

Performed clash analysis within the CAD model to identify and resolve conflicts between different systems and components.

Provided instructions for redesigning specific systems to ensure a seamless integration and avoid future issues during construction.

4.3D Data Optimization:

Optimized the 3D data for better performance and ease of use in the CAD software.

Ensured that the optimized model was user-friendly and efficient for further design and analysis work.

Key Outcomes

Accurate As-Built Model: Developed a precise 3D representation of the existing site, providing a solid foundation for future design work.

Integrated 3D CAD Model: Successfully transformed 2D plans into a detailed, integrated 3D CAD model, facilitating better visualization and planning.

Conflict Resolution: Identified and resolved potential clashes early in the design phase, minimizing costly revisions during construction.

Optimized Data: Enhanced the usability and performance of the 3D model, ensuring it was ready for further design, analysis, and eventual construction.

By creating an intelligent and optimized 3D CAD model of the as-built situation and preliminary design, we provided Johnson Matthey and Atrium DOO with a robust tool for planning and executing their new manufacturing capacity project. This approach not only improved the accuracy and efficiency of the design process but also helped prevent potential issues during the construction phase, ensuring a smoother and more successful project outcome.