CAD & BIM Modeling Services

Comprehensive 3D Data Processing for Industrial Projects

Why Choose Our 3D Modeling Team?

We always strive to deliver accurate 3D data that comprehensively describes our clients' projects. Leveraging our expertise and experience as mechanical engineers, we are focused on mechanical engineering projects ranging from MEP installations in residential buildings to complex equipment systems in manufacturing PDMS.

Depending on the nature of the project, we build 3D models from point cloud, technical documentation, draft drawings, or available project information, collaborating with the client from initiation to handover. Throughout the project, we adhere to all relevant standards, considering the client's needs, resources, and methods for easy management, viewing, and editing of the 3D model. Our team of experienced specialists and Mechanical Engineers prioritizes quality and timely delivery, ensuring the highest standards are consistently met.

So far we have established collaborations with world-renowned engineering consulting firms and global corporations in the Power, Oil and Gas, Petrochemicals, and Water and Waste Water Management sectors. These projects have earned certificates and commendations for excellence. Services are represented across the European and regional Balkan markets.

Below are the various types of 3D data processing and practical applications we offer:

FULL 3D SUPPORT IN MECHANICAL ENGINEERING PROJECT

We provide comprehensive 3D support for mechanical installation and operational projects, as well as architecture and civil engineering projects. Our expertise includes developing precise 3D models and implementing cutting-edge technologies throughout the planning, design, installation, handover, and production phases.

•Detailed 3D models that facilitate precise and comprehensive project designs.

•3D animation and simulation of activities and methods, offering visual insights into project execution and planning.

•Creation of Bill of Materials |BOM| documentation, streamlining project management and resource allocation.

•As-built 3D models, providing accurate representations of completed projects for future reference.

•Advanced methods for installation inspection, ensuring quality and compliance.

Our methods are widely adopted in various projects, including product upgrades, new equipment installations, overhauls, and documentation archiving. By leveraging the latest 3D technologies, we enhance project efficiency, accuracy, and overall success. Whether it's for visualizing complex systems, optimizing workflows, or ensuring precise execution, our 3D solutions are tailored to meet the unique needs of each project.

Additionally, our commitment to innovation and excellence means that we stay at the forefront of industry advancements, continuously refining our techniques and tools to deliver superior results. Trust us to transform your project ideas into reality with unmatched precision and expertise.

In the posts below, you can find more information about this type of service, as well as examples from customers who have implemented these services in engineering projects.

How can I get started with your 3D support services?

To get started, simply reach out to us with your project details. Our team will discuss your needs and outline how our 3D support services can enhance your mechanical engineering projects, ensuring a smooth collaboration.

Can your 3D models be integrated with other software?

Yes, our 3D models can be exported in various formats compatible with popular engineering software such as AutoCAD, SolidWorks, and Revit, facilitating integration with your existing workflows.

In which industries do you apply your 3D support services?

Our 3D support services are applicable across various industries, including manufacturing, construction, oil and gas, automotive, and aerospace, where precise modeling and visualization are crucial for project success.

How do you ensure the accuracy of your 3D models?

We ensure the accuracy of our 3D models through rigorous data collection methods, advanced modeling techniques, and ongoing quality assurance processes. Our team employs state-of-the-art tools and software to maintain high precision standards.

What is the typical turnaround time for creating 3D models?

The turnaround time for creating 3D models depends on the project's complexity, size, and specific requirements. We work closely with clients to establish timelines that align with their project goals and deadlines.

Do you offer training or support for using your 3D modeling tools?

Yes, we provide training and support for our clients to ensure they can effectively utilize our 3D modeling tools and software. Our team is available to assist with any questions or challenges that may arise.

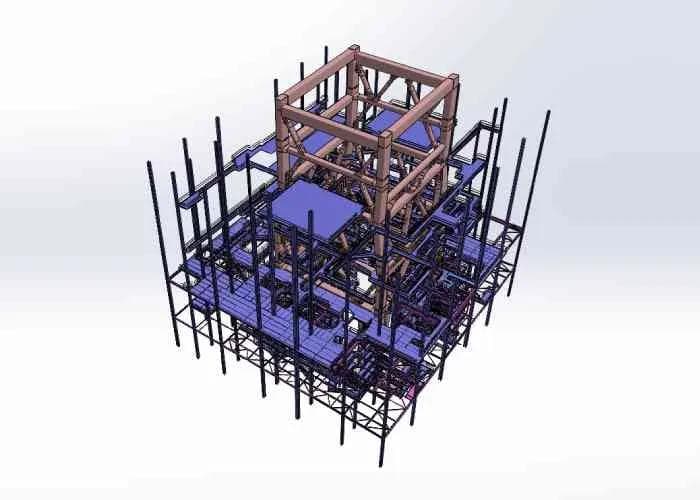

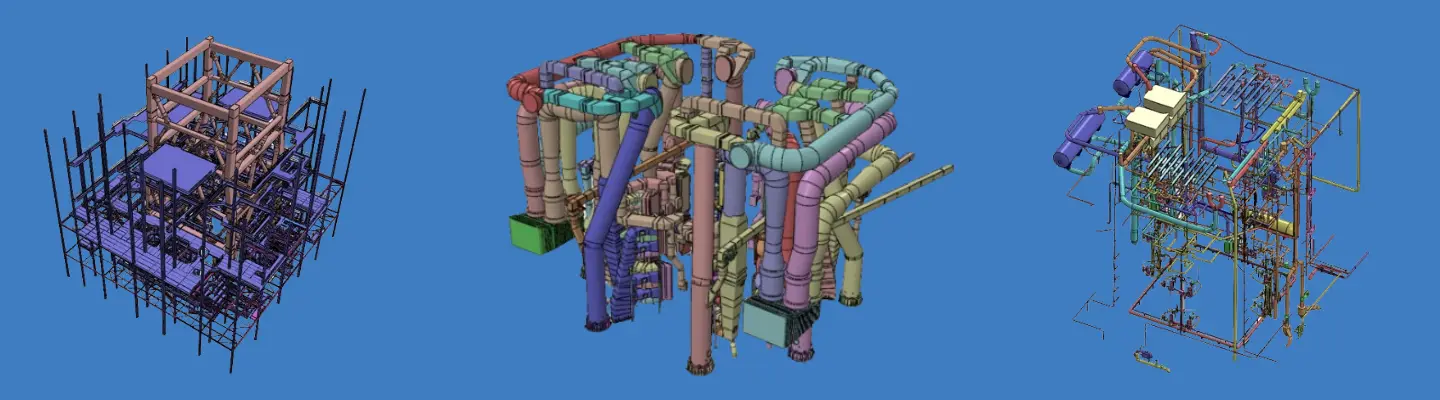

PDMS-Plant Design Management System and BIM-Building Information Modeling 3D Model

Our company specializes in building and deploying PDMS |Plant Design Management System| 3D models, a powerful design and engineering tool used primarily in the plant and process industries. PDMS enables engineers to design complex plant facilities, including oil and gas refineries, chemical plants, and water treatment facilities. The software allows the creation of detailed 3D representations of entire plant systems, including piping, equipment, structures, and electrical and instrumentation systems.

•Complete Plant Design:more ▼

•Captures all aspects of plant design:From equipment placement and piping layouts to structural components and supports.

•Real-time Collaboration:Allows multiple engineers and designers to work on the same project simultaneously, ensuring consistency and efficiency.

•Clash Detection:Identifies and resolves potential clashes between different components of the plant, reducing the risk of errors during construction.

•Data Integration: Integrates with other engineering and design tools, facilitating seamless data exchange and consistency across various project phases.

•Accurate Documentation:Generates detailed drawings and reports from the 3D model, aiding in project documentation and communication.

•PDMS 3D Models:essential for ensuring accurate and efficient design, construction, and maintenance of complex industrial facilities.

Our services include creating 3D PDMS models that range from non-intelligent to fully intelligent, tailored to meet client requirements.

•levels of Intelligence:more ▼

•Level 1 Non-Intelligent PDMS Models:Non-Intelligent PDMS Models: Models without logical grouping or tagging, typically used for specific imports.

•Level 2 Basic Non-Intelligent PDMS Models:Logical grouping of items/objects under individual names, providing a basic structure.

•Level 3 Partially Intelligent PDMS Models:Grouping of primitive items with reduced tagging, offering partial intelligence.

•Level 4 Enhanced Partially Intelligent PDMS Models:Groups of primitive items, piping, equipment, etc., with standard tagging for improved utility.

•Level 5 Fully Intelligent PDMS Models: Comprehensive models with full commercial tagging and naming, delivering complete engineering intelligence.

Our 3D PDMS models can also include specific spacing and routing features such as escape routes, hazardous area classification zones, maintenance and operation reserved areas, and pipeline right of way (ROW). These features ensure that our PDMS models are not only accurate and detailed but also practical and aligned with industry standards and safety requirements.

•Software Used for PDMS 3D:more ▼

•AVEVA PDMS:Used in the plant and process industries, including oil and gas, petrochemicals, and power generation.

•Autodesk Revit:Used in architecture, engineering, and construction (AEC) for creating detailed architectural designs and MEP systems.

•LOD Variations for PDMS 3D:more ▼

•LOD 100:Conceptual model for preliminary design and feasibility studies.

•LOD 200:Schematic design model for initial space planning.

•LOD 300:Detailed design model for coordination and clash detection.

•LOD 400:Fabrication model with precise specifications for assembly.

•LOD 500:As-built model representing the final condition of the project.

•Connectivity with BIM 3D:more ▼

•Data Interoperability:Seamless data exchange between PDMS and BIM software ensures consistency and accuracy.

•Integrated Workflows:Combining PDMS and BIM models for a holistic approach to design, construction, and facility management.

•Clash Detection and Coordination:Using integrated models to identify and resolve clashes between different systems and components.

•Enhanced Visualization:Combining PDMS and BIM models for advanced visualization and simulation.

•Lifecycle Management:Utilizing BIM models enriched with PDMS data for complete lifecycle management of the facility.

By integrating PDMS 3D models with BIM, projects benefit from improved accuracy, better coordination, and enhanced project management throughout the entire lifecycle. This approach leverages the strengths of both systems to deliver high-quality, efficient, and effective solutions.

In the posts below, you can find more information about this type of service, as well as examples from customers who have implemented these services in engineering projects.

What is BIM, and how does it integrate with PDMS?

BIM, or Building Information Modeling, is a digital representation of a building's physical and functional characteristics. Integrating BIM with PDMS enables better coordination, enhances data sharing, and supports more effective project management across the lifecycle of industrial and plant projects.

What is PDMS, and how does it benefit plant design?

PDMS, or Plant Design Management System, is a 3D modeling software primarily used in the plant and process industries, such as oil and gas, chemical, and water treatment facilities. It allows engineers to create comprehensive 3D models of plant systems, including piping, equipment, and electrical systems, ensuring accurate, safe, and efficient plant design.

Can PDMS models include safety features like escape routes and hazardous zones?

Yes, our PDMS models can include critical safety features such as escape routes, hazardous area classification zones, maintenance zones, and pipeline right-of-way (ROW). These features help ensure that the models are not only detailed but also aligned with industry safety standards.

What is the difference between intelligent and non-intelligent PDMS models?

Intelligent PDMS models contain metadata and embedded information, making them useful for simulations, analysis, and operational planning. Non-intelligent models, on the other hand, are basic 3D representations without additional data, primarily used for visualization purposes.

What is LOD, and how does it apply to PDMS models?

LOD, or Level of Detail, refers to the amount of information contained within a model. Our PDMS models offer various LODs, from basic to highly detailed, depending on the client’s requirements and the project's complexity, ensuring optimal balance between model detail and project scope.

Can you tailor PDMS models to specific industry standards and client requirements?

Yes, we customize our PDMS models to align with specific industry standards and individual client needs. This includes adapting models to comply with local regulations, incorporating client-specific safety and operational zones, and ensuring precise spatial configurations.

How are PDMS models used in different stages of a project?

PDMS models are used throughout the project lifecycle, from initial planning and design through installation and operation. They help in visualizing complex systems, assessing spatial requirements, planning escape routes, and ensuring compliance with safety standards, thus enhancing project coordination and management.

CAD & AS-BUILT 3D Modeling Services

At our company, we offer advanced CAD and AS-BUILT 3D modeling services tailored to meet the diverse needs of our clients in the mechanical engineering sector. Our expertise spans from creating basic CAD models using simple primitives to developing detailed AS-BUILT 3D models derived from point cloud data.

•CAD Models from Simple Primitives:more ▼

We understand that each project has unique requirements. Depending on the client's needs, we create CAD models starting from simple geometric primitives like cubes, cylinders, and spheres. These basic shapes are the building blocks for representing the current state of parts, machines, systems, or entire industrial plants. Our CAD models serve as an essential starting point for project preparation, design, and implementation. Using industry-leading software such as AutoCAD and SolidWorks, we ensure that these models are precise and reliable, facilitating efficient project planning and execution.

•AS-BUILT 3D Models from Point Cloud:more ▼

For more complex projects, we provide AS-BUILT 3D modeling services that capture the true state of existing structures. Utilizing high-resolution 3D scanning technologies, we gather detailed point cloud data that represents the exact surface geometry of objects. This data is processed using tools like Autodesk ReCap and Leica Cyclone to generate accurate 3D models. These models offer a comprehensive visualization of the built environment, crucial for documentation, maintenance, inspections, and retrofitting projects.

•Integration & Hybrid Modeling:more ▼

Our services also include the integration of simple primitives with detailed AS-BUILT models, providing a flexible and efficient approach to modeling. This hybrid method allows us to create initial frameworks using simple shapes and refine them with detailed point cloud data as needed. The result is a highly accurate model that meets all project requirements.

•Applications and Benefits:more ▼

Our CAD and AS-BUILT 3D models are used in various applications, including:

•Project preparation and design

•Maintenance and inspection planning

•Retrofit and renovation projects

•Documentation and archival

With our comprehensive modeling services, clients benefit from improved project accuracy, better communication among stakeholders, and enhanced project outcomes. Trust us to deliver high-quality, precise models that support your engineering needs from start to finish.

In the posts below, you can find more information about this type of service, as well as examples from customers who have implemented these services in engineering projects.

What software do you use to create CAD and AS-BUILT models?

We use leading industry software such as AutoCAD, Revit, SolidWorks, and specialized point cloud processing software to ensure that our models are compatible with various platforms and meet client requirements.

What types of CAD models can you create?

We create CAD models ranging from simple geometric primitives to complex, detailed representations based on project requirements. Our CAD modeling services can be customized for various applications, from basic design concepts to intricate mechanical components and assemblies.

What is the difference between CAD models and AS-BUILT 3D models?

CAD models are typically created from scratch using design specifications, while AS-BUILT 3D models are generated from actual point cloud data captured from the physical site. AS-BUILT models reflect the real-world conditions of a project, making them ideal for documenting existing structures or installations.

How are AS-BUILT models created from point cloud data?

AS-BUILT models are created by capturing point cloud data of the existing environment using laser scanning. This data is then processed to create a precise 3D model that accurately represents the current state of the structure or installation, allowing for detailed analysis and planning.

What is hybrid modeling, and when is it used?

Hybrid modeling combines CAD and AS-BUILT data to create a comprehensive model that reflects both design specifications and real-world conditions. It’s particularly useful in retrofit or upgrade projects, where new components need to fit seamlessly within existing structures.

How accurate are the AS-BUILT 3D models created from point clouds?

Our AS-BUILT models have high accuracy, typically within a tolerance of ±1mm between the scanned object and the resulting point cloud. For final 3D models, accuracy can be tailored to meet specific project requirements, ranging from ±1mm to ±1cm, depending on client needs.