Published by:

Dalibor Vuchikj

10 Apr 2024

My vision is to support companies and organizations in the development and implementation of mechanical engineering and operational projects. As a Mechanical Engineer by education, combined with a deep passion for new technologies. Specialize in offering cutting-edge digital methods and technologies, including 3D scanning, intelligent 3D modeling, documentation, 3D data processing and optimization, analysis, simulations, VR integration, and more.

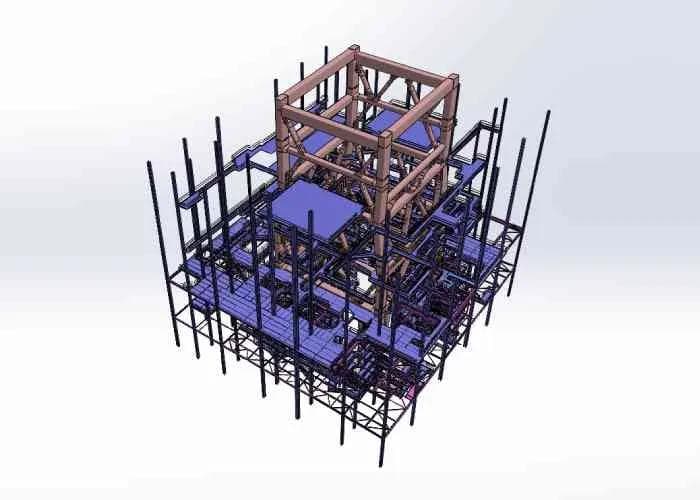

Analyzing Industrial Grade Metal Structures with PDMS 3D Models

Our digital models replicate existing industrial-grade metal structures, providing a virtual mirror of real-world conditions. These models enable comprehensive analysis of deformation and expansion under various external influences and loads, critical for maintaining structural integrity.

Detailed Deformation Analysis

Through meticulous analysis, we identify the most heavily loaded and irreversibly deformed metal segments. This insight allows us to reinforce stressed segments and replace those beyond repair, ensuring deformation remains within acceptable limits.

Accurate Deformation Measurement

We define deformation by comparing the 3D model from the project documentation with the as-built 3D model derived from point cloud data. Utilizing a PDMS (Plant Design Management System) 3D model composed of simple geometric forms ensures that clients receive data that is easy to load and manipulate.

Simplifying Data Handling

While using a mesh derived from point cloud data to compare with the project documentation's 3D model is possible, it complicates data handling for large industrial capacities. This approach often restricts the use of various 3D software packages, making PDMS models a more practical solution.

Simulation of Stress and Deformation

We can simulate stress and deformation on the as-built 3D model upon request. For the PDMS model, establishing intelligent connections between metal segments is crucial. This process results in a 3D BIM (Building Information Modeling) model, which predicts future deformation and stress on the metal structure, aiding in proactive maintenance.

Conclusion

In conclusion, analyzing metal structures in a virtual environment using tailored 3D models is faster, more efficient, and cost-effective. This approach is designed to cater to specific uses and allows for potential future improvements.

We hope this clarifies our process. If you have any questions, please feel free to ask.