Published by:

Dalibor Vuchikj

4 Nov 2021

My vision is to support companies and organizations in the development and implementation of mechanical engineering and operational projects. As a Mechanical Engineer by education, combined with a deep passion for new technologies. Specialize in offering cutting-edge digital methods and technologies, including 3D scanning, intelligent 3D modeling, documentation, 3D data processing and optimization, analysis, simulations, VR integration, and more.

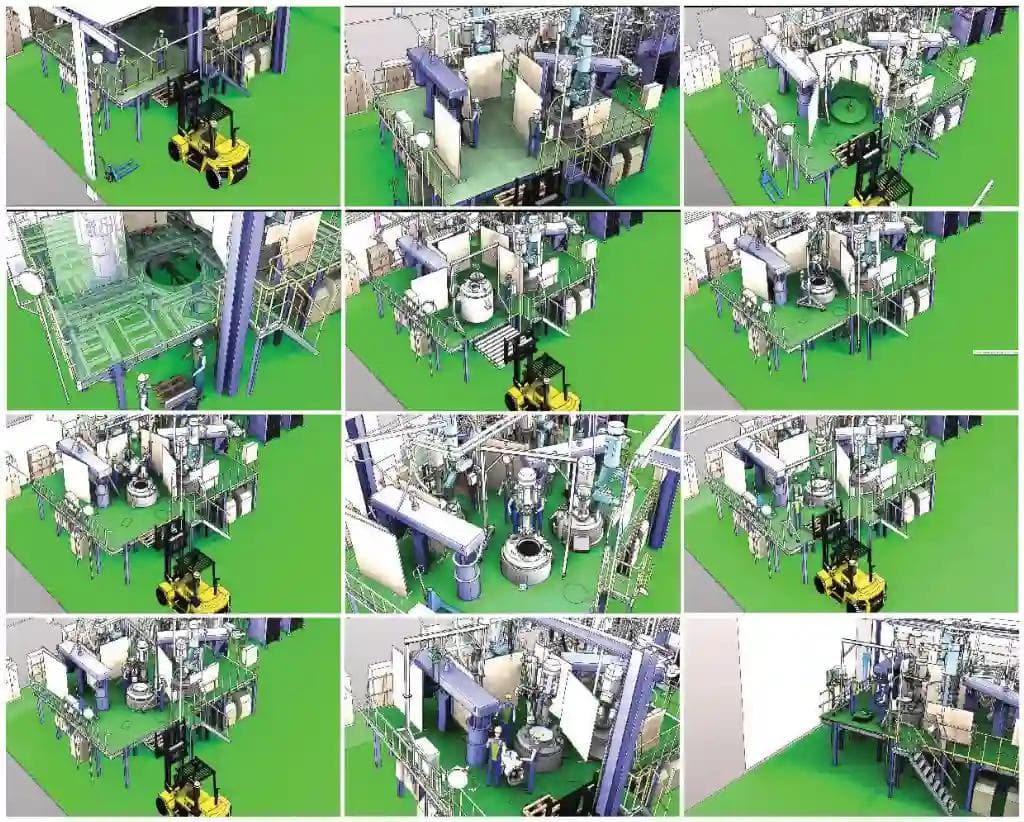

Method Of Installation Simulation And Analysis In Virtual and Augmented Reality

In the realm of mechanical installations, reducing the risk of incidents and accelerating the process of installing additional equipment is paramount. By simulating and controlling the process, we can achieve significant improvements.

Creating a digital twin of an existing machine installation, combined with a detailed CAD design of the new equipment, allows us to conduct comprehensive risk analyses and establish control by meticulously planning the installation course.

This is implemented through detailed simulations of installation actions. Each activity is analyzed, planned, and controlled separately. 3D visualization and time-based simulation help identify the most efficient and safest methods for completing the installation.

The digital twin facilitates the precise construction of new equipment onto the existing installation, minimizing risky on-site activities and saving valuable time. Accurate planning encompasses all activities, from transporting the equipment to the site to executing all installation steps.

All necessary protective measures are implemented according to the nature and risk level of each activity. The time interval for each activity is meticulously determined, making the installation process more accessible through visual representation. This enables all project participants, including those without technical backgrounds, to understand the installation process and contribute their expertise effectively.

The entire simulation can be conducted in virtual reality, offering a more immersive experience of the installation process and enhancing safety and efficiency. Additionally, the installation process can be presented on-site using augmented reality technology. With a smartphone or augmented reality glasses, it is possible to monitor the entire installation step-by-step using a 3D model from the machine installation design.